Description

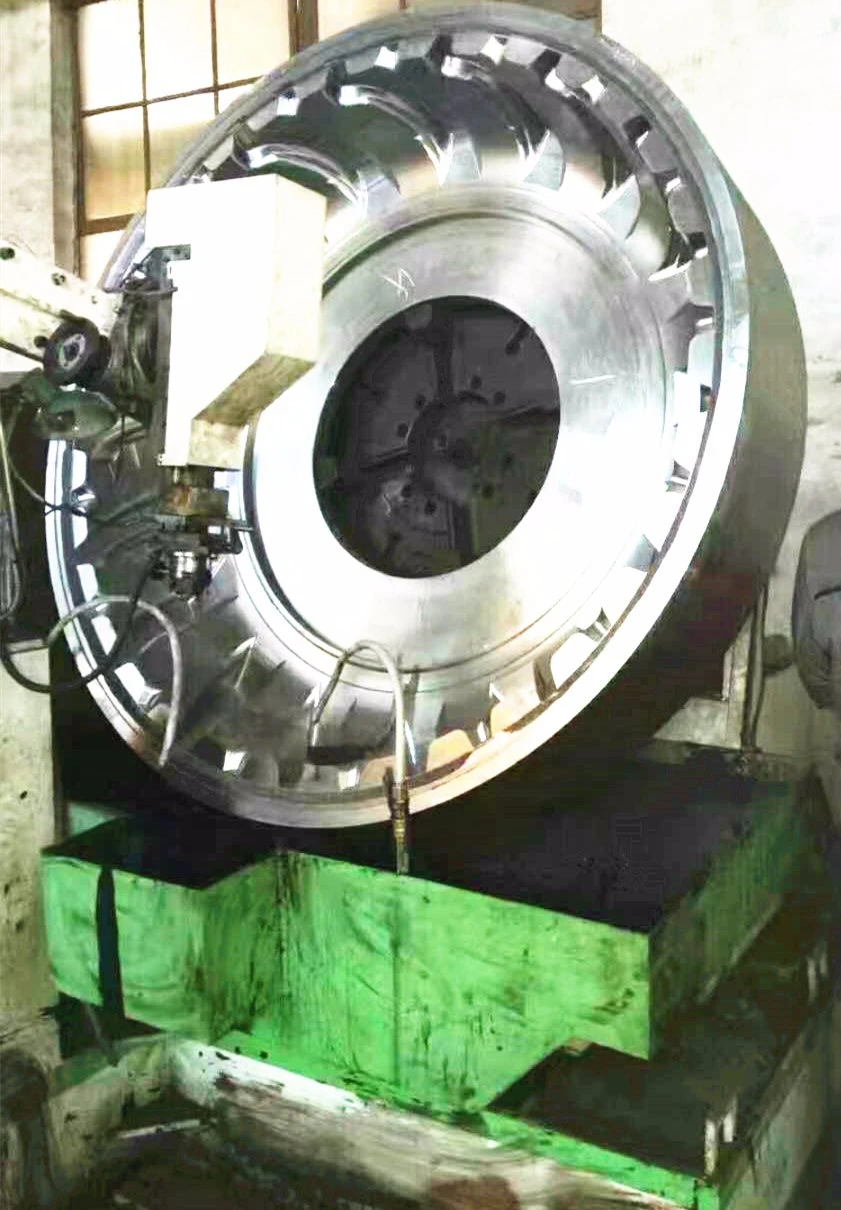

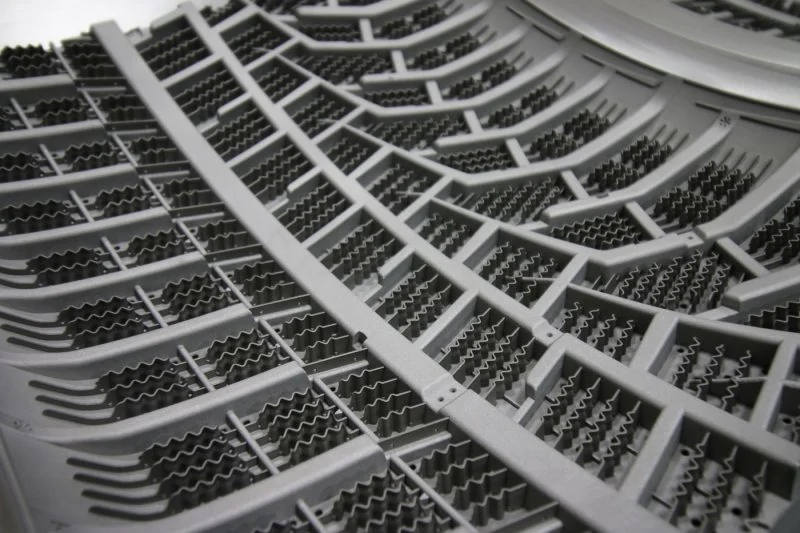

F1050 is a special EDM machine developed by our company five years ago, based on the needs of customers and the advantages of F900, for two-peices tire molds and segmented molds up to 2500KG. It is continuously perfected and optimized in use and is recognized by customers. F1050 has a large bearing capacity and a rotary diameter of 1400mm. It is suitable for the tire manufacturer to reduce the cost of segmented tire molds and use low-cost two-pieces tire molds to manufacture cars, off-road vehicles and BUS tires.

The F1050 is suitable for the machining of segmented tire moulds with guide rings.

Jinan Zhengri Technology Co., Ltd. was established in 2003 and has been devoted to the research and development and production of vertical CNC milling machines and EDM machine tools. Founded in 2003, it has more than 15 years of experience in R&D and production of vertical CNC milling machines and EDM machine tools. Our company has accumulated ESD core technology for many years of research and development, and has patented technology of electric spark resistance source circuit (patent number: 201922302290.6). In 2012, our company successively introduced high-precision metal engraving machine tools and vertical 850 CNC milling machine bodies, graphite engraving and milling machine and other high-precision sharp CNC machine tools on the basis of the previous technology accumulation, and we produced vertical VCM850 vertical CNC milling machine bodies The body of the He carving and milling machine, the full casting structure, the product has high stability, and the accuracy is 1 wire, which is praised by customers.

Our history

2003 In 2003, it was founded by 5 senior engineers of state-owned machine tool factory, and was named: Jinan Zhengri Technology Co., Ltd.

2004-2006 The workshop was put into use, mass production of EDM machine tools

2007 Started production of 400/500 graphite engraving machine/engraving and milling machine supporting EDM machine tool

2008 Started R&D of ESD unimpeded power supply

2009 EDM power supply 150A electric cabinet supporting rectangular tire mold EDM machine tool

2010 EDM unimpeded power supply supporting tire mold EDM machine tool

2011 The new R&D center was established and put into use. 500 Series Carving Machine/Carving Mill Supporting Tool Magazine

2012 Research and development of four-axis engraving machine/engraving and milling machine, swing head B-axis harmonic reducer

2013 R&D of the third generation climbing circuit of ESD unimpeded power supply

2014 The hydrological plant was put into use, and energy circuits such as electric spark power supply were successfully developed

2015 1280 gantry machining center development

2016 Purchase of large-scale grinding machines and boring machines, 80% of machine tool parts are processed independently

2017 R&D of 5-axis engraving machine/engraving and milling machine

2018 Successfully renovated Taiwan's BXT and SIT cabinets due to tire mold sparks

2019 Trial production of desktop-grade small five-axis machine tool succeeded

Main Features

1. F1050 is designed for motorcycle, bicycle, agricultural vehicle, car, BUS two-pieces tire mold processing.

2. The worktable can be tilted back and forth for easy mold installation.

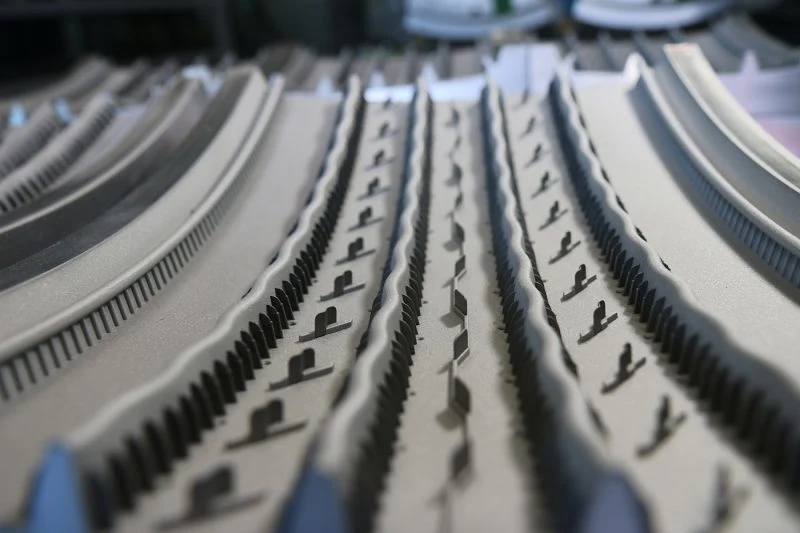

3. Tread pattern bottom surface finish is the same

4. Y-axis is electric, easy to install tire mold up and down

5. The spindle head is equipped with a universal adjustment clamp to facilitate electrode adjustment.

6. The processing parameters can be modified from time to time in the tire mold processing to optimize the mold quality.

7. The F1050 working disc is mounted on the headstock, and the closed-loop CNC turntable drives the headstock. The weight of the tire mold of this structure is borne by the headstock, which avoids the direct force of the worm wheel of the CNC rotary table, reduces the force of the CNC turret, and makes the rotation precision higher, and the weight of the tire mold can reach 2500kg.

Specification

| Items | Unit | D2800 |

| X Travel | mm | 70 |

| Y Travel | mm | 490 |

| Z Travel | mm | 180 |

| Table Diameter | mm | 2800 |

| Cutting Accuracy | " | 10 |

| Spindle Rotation | ° | 360 |

| Max. Electrode Weight | kg | 50 |

| Max. Workpiece Weight | kg | 3500 |

| Max. Workpiece | mm | 200-1250 |

| Max. Workpiece Width | mm | 380 |

| Dielectric Fluid Reservoir | mm | 1300*650*320 |

| Max.Electric Current | A | 100 |

| Power Supply | V | 380V |

| Input Power | KVA | 7.5 |

| Min. ON TIME | μs | 2 |

| Min. OFF TIME | μs | 2 |

| Max. Working Speed | mm/min | 2000 |

| Best Surface Precision | μmRa | 0.04 |

| Min. Electrode Wear Rate | % | <0.3 |

| Machine Unit Dimensions (W x D x H) | mm | 2700*1400*3000 |

| Machine Unit Weight | Kg | 4100 |

Company