GT series is a new type of EZ CNC engraving and milling machine with high quality, atmosphere and upper grade. Using high quality, atmosphere and upper grade. Using 40mm innovation dual ball screw with driven nut, speed up to 60m/min, with Spain fagor controller, and import parts, to ensure high speed operation, while ensuring high precision and high stability of engraving. It is the only choice for seeking perfect processing quality.

Innovative Dual Ball Screw With Driven Nut Technology

EZ GT series adopt innovative dual ball screw with driven nut technology. Ball screw is a product what converts the rotary motive into a linear motion or a linear motion into a rotary motion. The ball screw was widely used in industrial machines and precision instruments. Because the ball screw would support some advantages, such as slowing wear resistance, improving high transmission efficiency, making transmission smoothly, improving precision, making temperature rising slowly. GR series can make accuracy error less than 0.01, speed up to 60m/min.

Driving System

EZLETTER GT series adopted Japan imported YASKAWA digital servo. Comparing with step motor drivers, it is more precise than step motor drivers. So that each turn of the servo motor to the servo drive and CNC control system output 16384 pulses for feedback control. The use of servo systems can be overloaded, which means higher speed, faster acceleration and greater cutting force.

GT series gantry machining center adopted dual ball screw technology, it would largely enhance shock resistance, reduce the vibration about ten times. Adjusting dynamic characteristic, the acceleration of 3 axes will be increased to 1G. According to adopt innovation dual ball screw, the gantry and the spindle will be keeping balance when the machine is working. It is a great way to enhance stability, precision, speed.

Italy HSD Spindle

Power: 380V/9kW

Spindle Speed: 24000rpm

Air cooled

Advantage:

1. Adopting high speed chunk and nut with working stability, high speed.

2. Passing strict dynamic balance, and satisfy requirements of high speed

3. It contained the function of automatic tools changer

4. As for customer requirements, we can use the Angle Head spindle function, it is a new technology to drill the hole by the sides of material.

Fagor Controller

Fagor Automation offers an integral solution to high performance machining centers and production lathes because of our large selection of features. Our CNC systems meet the most demanding requirements. The range of CNC's goes from conversational programming CNCs for short production series that require quickness to high-speed CNCs with nanometric accuracy for machines of high technological value or CNC systems for specific applications such as Laser cutting, etc.

Fagor CNCs are designed for all kinds of machines with additional benefits:

-Easy programming. There is no need to know ISO programming language.

- Algorithm that provides the best performance, speed and accuracy in

the machining process.

- Ergonomic and functional design (touch-screen, easy navigation,

integrated manuals, sms communication, high-resolution graphics,

keyboards and monitors with the highest level of sealing protection,

etc.)

- Interface customizing tools.

- Free software download with no time limit to work at any PC.

- Axis position control (position loop) every 250 s.

- Technological features like Look-Ahead. The CNC analyzes in advance the changes in the

movements of the axes providing high speed machining. Our CNCs analyze 2,400 blocks in

advance and block processing time is 0.25 ms.

Carrousel Tools Changer

GT Series adopt carrousel tools changer, comparing to linear tools changer, this technology will be better because it could contain 8 knives. The route is shorter that the linear tools changer. The ATC would save much time in tools changing. Then, we add dust cap on the equipment, dust will be isolated to knife and the durability of knife will be expanded. Considering some situation of tools collision, this equipment was installed a reliable air collision avoidance system.

Vacuum Table

Vacuum system can materials on the table surface, comparing to the traditional manual clamping, it will improve production efficiency. The material is adsorbed on operation table, the middle of the material will not appear shifting. At the meanwhile, each partition is a separate part, the seal was made from special materials with waterproof and oil resistance.

Automatic Tool Sensor

Auto calibrate tool sensor, it can write all tool parameters into the system through automatically calibrate and save much time comparing with traditional manual calibration. For presetting the tool length with an accuracy of 0,01mm.

Software

GR Series can work through some software which will output G code, for example: Wentai engraving software, Jingdiao engraving software, Type3, ArtCAM, AlphaCAM, AutoCAD, Cimatron, MasterCAM, Enrouter. According to the customer requirement, we also can support V-Carve Pro software service.

Compressed Air Specification

To ensure proper operation of devices installed on the machine that use compressed air, and in particular the spindle, the compressed air supplied must comply with the following characteristics

Inject compressed air with a purity rating complying with ISO 8573-1, types 2, 4, 3,

i.e:

- Type 2 for solid particles: size of solid particles < 1 m.

- Type 4 for humidity: dew point < 3°C (37.4°F).

- Type 3 for total oil: oil concentration < 1 mg/m3

2. Specification

| Model | GT2030 | GT2040 | GT2550 |

| Size(m*m) | 2.0*3.0 | 2.0*4.0 | 2.5*5.0 |

| X-dual motor | √ | ||

| Servo | √ | ||

| Axis | 4 | ||

| Z clearnce | 200mm | ||

| Vacuum zone | 6 | 6 | 6 |

| Spindle power(KW) | HSD9.0ATC/HSD12.0ATC | ||

| Spindle speed | 24000rpm | ||

| Collect | ISO30 ER32/ HSK F63 ER40 | ||

| Auto surface | √ | ||

| Gantry Axis | √ | ||

| Speed(X,Y Axis) | 60m/min | ||

| Speed(Z Axis) | 30m/min | ||

| Weight(Ton) | 3.5 | 4.0 | 4.5 |

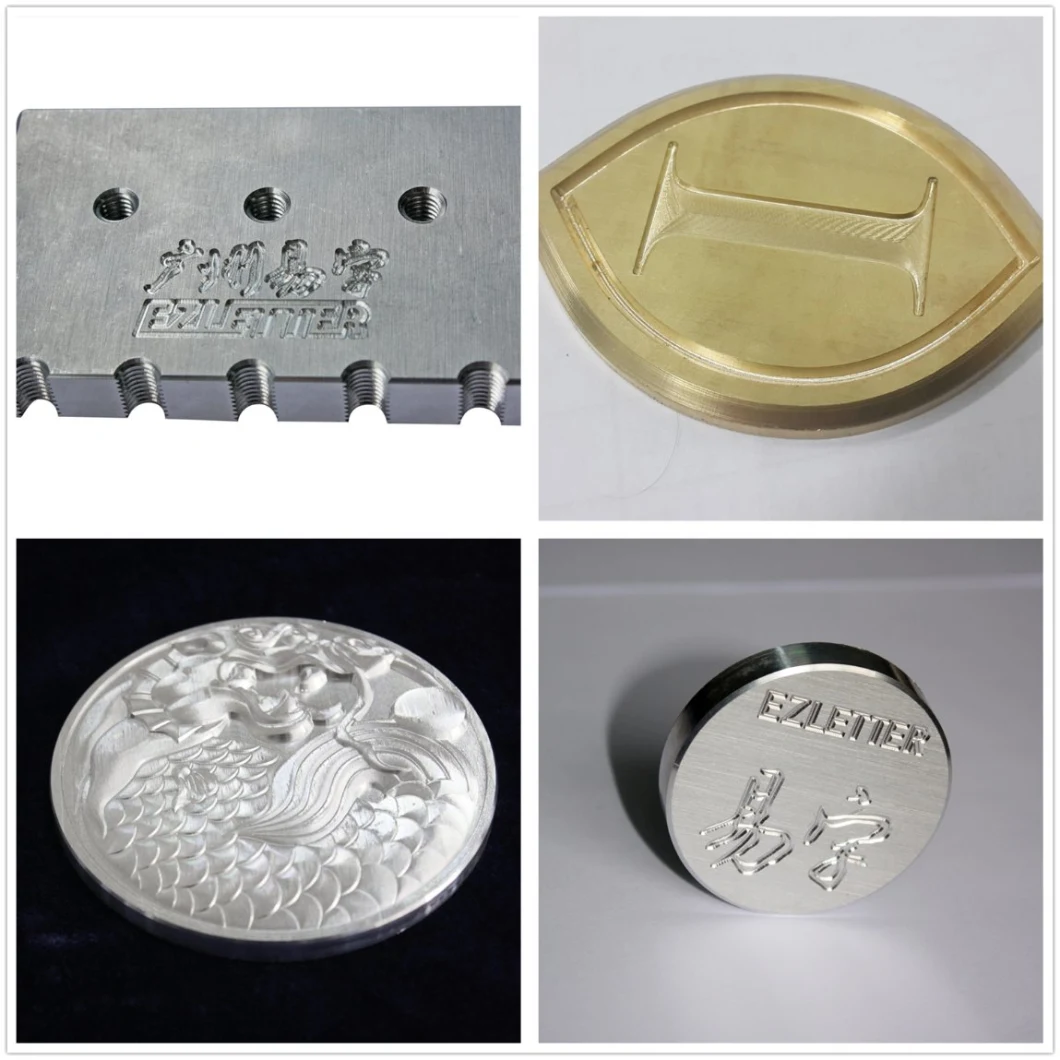

3. Application Industry and Materials

The advertising Industry: CNC router can engrave all kinds of signage, logo products, trademarks, nameplates, badges, decorative gift, embossed

Woodworking Industry: CNC router can be used for solid wood furniture, mahogany furniture, MDF paint doors, solid wood doors, composite doors, cupboard doors and windows, beside cabinets, folding screen etc.

Medals, certificates, souvenirs, photo frames, furniture decoration, PVC plates, PCB boards(drilling and engraving), Double color boards, acrylic etc.

Artwork Industry: In the wood, bamboo, organic board, double color plate, crystal and other materials on a variety of exquisite patterns and text engraving, Acrylic Cutting etc.

Soft Metal Processing: Aluminum cut and drill, Aluminum carving and grooving, Copper and Aluminum processing etc

Exhibition Industry: Showcases, etc.

PERFECT SAMPLES

4. About EZLETTER COMPANY

EZLETTER founded in 2006, is the first company established in China to research and develop, produce and sell the Automatic Channel letter bending machines. It has created a brand-new industry on the Automatic channel letter bending machines, provided equipment and technical support for Chinese companies to be the international leaders in making 3D LED signs, contributed a force for the flourishing development of advertising industry.

Since the creation, we have insisted on technological innovation and pursued the perfect quality. With innovation dual ball screw driven nut EZCNC Routers and Fiber laser cutting machines are fashionable in Europe and China high-end market. The Ezletter keypad controller with fully autonomous intellectual property rights is widely loved and praised by the market. Ezletter brand is becoming famous for the high precision, high speed and high stability. After more than 10 years of development, it has been formed the construction of one factory, one research and development center and four major divisions.

There are many professional and skilled talents in Ezletter. We have research and development teams on software, mechanical and electrical, as well as the service team with experienced technical staff members and production team with craftsman spirit. "Professional, Serious, Responsible, Friendly" is our core values. And we will go on working hard to provide differentiated values for the customers.

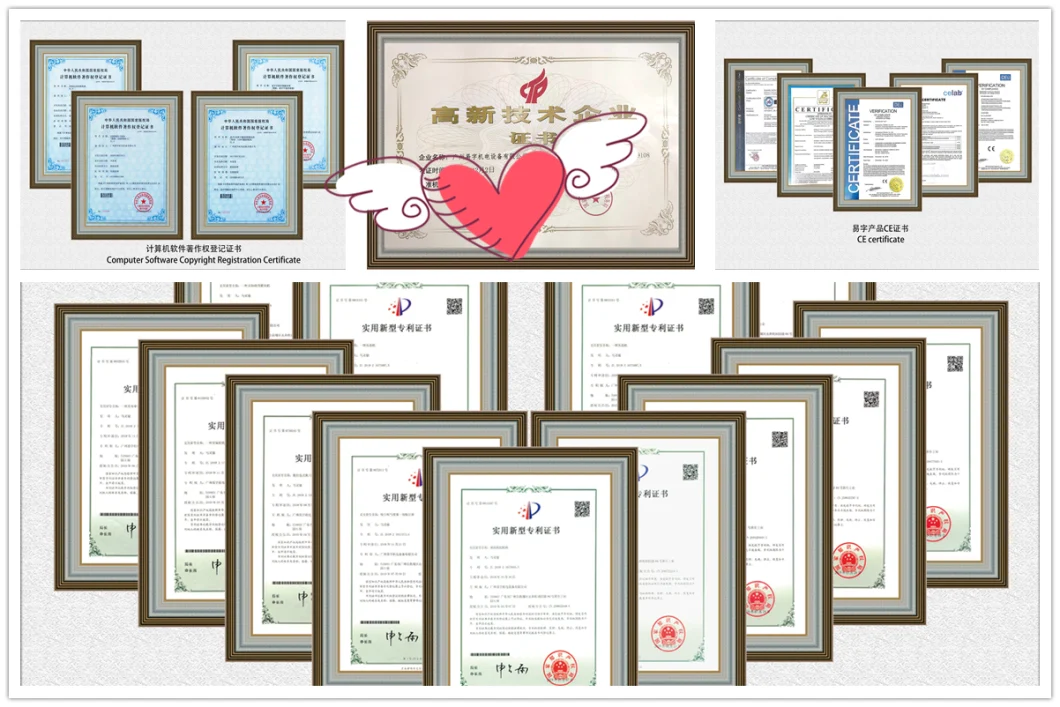

Since establishment, EZLETTER has been insisting on technological innovation, pursuing perfect quality, and constantly launching new high-tech products that meet the high demands of the market. Continuously launch new products, serve global customers, and lead the international leading level of bending machines, engraving machines and laser machines in the sign industry! Provide high-tech identification equipment for global customers and strive to innovate! Therefor EZLETTER have achieved a lot of Patents and Certificates.

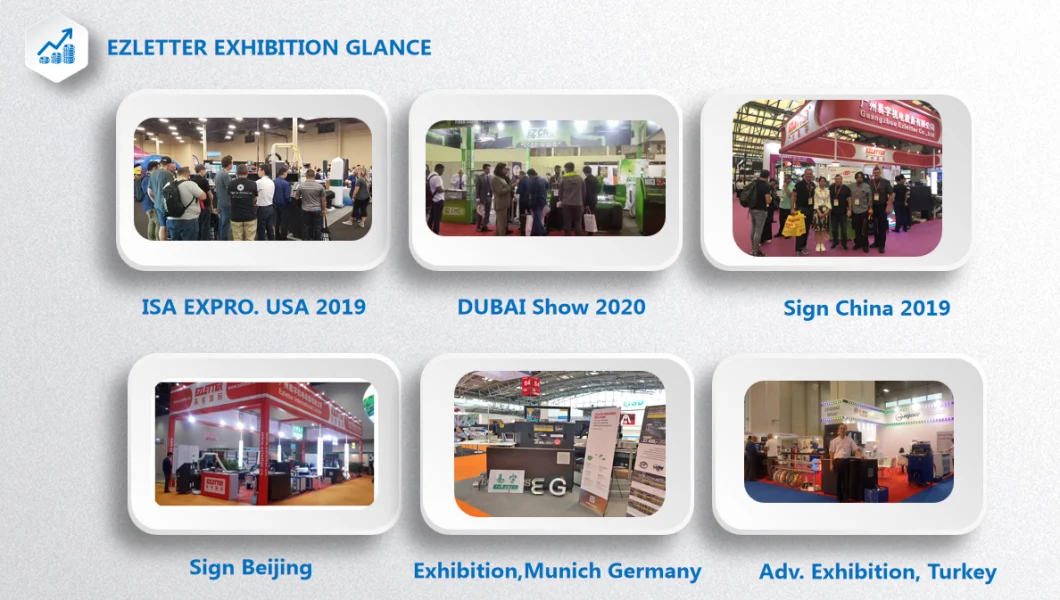

We took actively part in all the relevant well-known Exhibitions and EXPO. held around the World since foundation of 2006.

EZLetter have won a large number of Honour Certificate in the aspects of Technology Creation(Pls. see the attached pics).

Here show you a few pictures and videos of showing on exhibitions FYR:

EXHIBITION GLANCE

EZLETTER on Dubai Show 2020 https://youtu.be/UXIwuHN-1ns

EZLETTER Machines OverView https://youtu.be/B8hkd1tMq38

EZ other CNC router machines for your reference

Factory Workshop Live

5. Packing & Delivery

With more than 15 years exporting experience, we are so skilled for loading containers and packing the machines in container for safety.

Packing & shipment:

Save space as much as possible for container loading.

Inside: Water-proof Plastic Film Package With Foam Protection

Outside: Solid Seaworthy Wood Box Package or Blue waterproof canvas packaging

Below: Steel or Wooden Pallet

6. Service and Technician Support

(1) Our service:

Before sale:

We would always be here to provide any information you need at the first time, and give professional suggestions according to your real needs for free;

During sale:

We would deal with all the production and shipping affairs, after everything is ready, we would tell you everything goes well here;

After sale:

We would provide English Version working manual.

If you have any questions during using and maintaining, our engineers who could speak very good English would answer you online or by calls.

Machine warranty is one year. So if your machine has any unintentional damages, we would provide parts for free.

If your machine has big problems if by any chance, our engineers would arrive there to debug and fix or Provide On-line Support for Free!

Our professional after sale service team which are selected by very strict examinations, would pay their 100% time and energy to solve your problems!

(2) Technician Support

(1): Ezletter can send technician to the customer's country to provide the training if customer required.

(2): Customer will help Ezletter to solve the visa (available) and provide round flight tickets and Hotel and food while he stay in customer's country.

(3): The whole machine will be warranty one year.

We offer a 12 months warranty carefully, solve all customer's problem reasonably and justly.

(4): On-line Support Service

24 hours telephone line is available for any question.

Experienced service technician team is available.

Support in hard work solution.

7. FAQ:

(1). How long about the machine's guarantee?

2 years

(2). How about your after-sales service?

Technical support by phone, WhatApp, Skype, e-mail or QQ around the clock.

(3). How can we install the machine?

English version manual and operation video CD disk.

(4). How about the payment terms?

30% T/T for deposit, 70%T/T paid before shipping. T/T, West Union, Paypal

(5). Do you Arrange Shipment For The Machines?

Yes, dear customers, for FOB or CIF price, we will arrange shipment for you.

For EXW price, clients need to arrange shipment by themselves or their agents.